Hunter Rifleworks Rifles are made in Texas by a small team of dedicated employees.

Our method is similar to that of other premium products, one person is dedicated to the build of your rifle from start to finish. This ensures that pride in workmanship is paramount to the person making the rifle and every part is tested, hand fitted and assembled correctly.

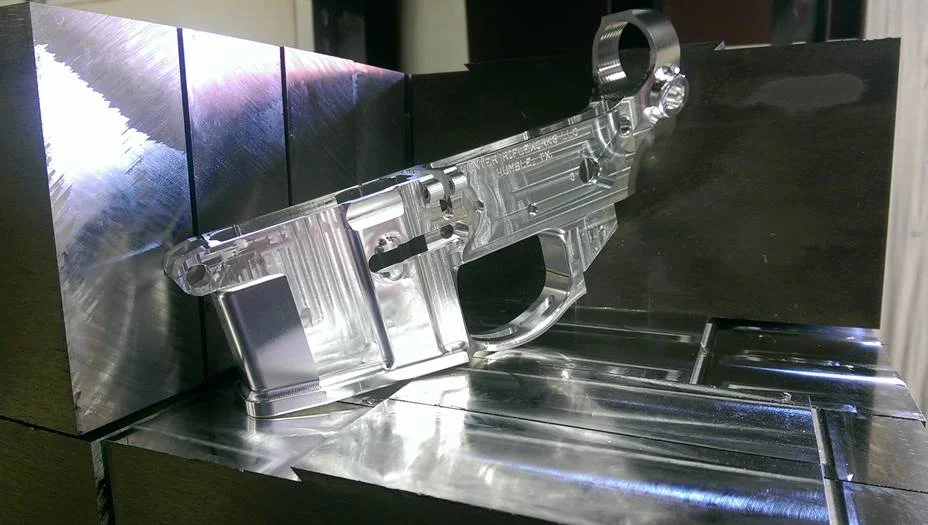

The uppers, lowers and handguards start from a solid block of 7075 T6 Aluminum and are cut on a Makino A51NX 5-Axis mill.

We partner with top tier ISO 9001 and AS 9100 manufacturer 2A-Armament in order to produce AR-15 pattern lowers, uppers and hand-guards of exceptional quality. Taking a block of metal and reducing material until the shape is formed are commonly known in the firearms industry as 'billet' products.

Billet has several advantages over more traditional forged parts. It is possible to make more complex shapes, and smaller custom runs, allowing us to modify and fine tune tolerances and design to fit the needs of the desired end product as well as quickly react to the market and introduce innovative features.

Once we have a machined and anodized (a form of protective hard coating) the upper and lower we begin the many processes needed to complete a rifle, many of which are above and beyond the measures taken by a more pedestrian manufacturer, and we think this attention to detail shows in our end result.

The accurizing process begins with our upper receivers where we ensure that the front of the upper is square, allowing for a complete and reliable mating of the barrel and extension to the upper receiver, and ensure that the bolt is 100% in line with the barrel extension. Even though very tight tolerances are kept in the machining process this hand lapping adds an additional measure of certainty that your gun will be as accurate as possible.

We use a variety of barrel manufacturers based on purpose and need.. We use mid-length gas where possible as opposed to carbine this ensures more consistent unlocking, slightly longer bolt dwell time and lower chamber pressures. Combined this allows the case ample time to expand, send the bullet down the barrel and allowing the brass to contract before the bolt unlocks and starts to withdraw the case from the chamber.

We use titanium barrel nuts to ensure the maximum strength with minimum weight and minimum thermal expansion. For all rifles we follow the same principle. Threads are treated with heat resistant grease and the nut is threaded on and tightened to 30ft.lbs several times to remove burrs and other friction points that could have happened during manufacturing. The nut is then tightened as per Colt factory specs to between 30-80 ft.lbs, ensuring alignment of the nut to allow the gas tube to pass through the nut.

We use titanium gas blocks on as many builds as possible. Not only is the set screw recessed, it also creates its own bite into the barrel material and finally is chemically fixed with heat resistant compound so that it will not loosen over time. This allows us to use very low profile and very lightweight gas blocks, ensuring that the weight is correctly distributed throughout the gun.

In order to ensure complete reliability, Hunter Rifleworks builds feature a custom bolt carrier group.

The carrier is 8620 steel as per mil-spec and is full weight/full auto to ensure dual use in law enforcement rifles as well as civilian products. The gas key is where things start to change in comparison to other manufacturers offerings. The enhanced BCG key is gas adjustable, meaning you can adjust the flow of gas through the system, allowing only just enough gas to ensure reliable operation and therefore reduce recoil impulse and fouling in the upper receiver. It also allows for adjustment of the system when using a suppressor and reduces the gas blowback. They key is staked as per mil-spec.

Click on the above picture for an in-depth explanation of the bolt carrier group.

To finish the bolt carrier it is laser engraved with the Hunter Rifleworks logo and kept black in color so that the bolt is recognizable but low profile.

In order to ensure perfect alignment and the minimum needed adjustment of sights to zero, the fore-ends are fixed in place whilst being supported and rails aligned using specialized tools. This ensures that the alignment is as true as possible and allows a parallel sight plane to the barrel.

Finally the flash hider is fixed in place, with 14.5" barrels a longer flash hider is used to reach the minimum legal length of 16", and it is pinned and welded into place.

The AR15 lower has less affect on accuracy than the upper receiver, however we ensure that this also receives due care and attention to detail when assembling in order to deliver the best product.

Many high quality parts are used in the creation of a Hunter Rifleworks rifle with the lightweight rifle, many of those parts are titanium

In all Hunter Rifleworks AR15 products, specialized triggers are used. The ALG series of triggers represents a superior solution that standard milspec triggers, giving a hardlubed and snag free pull and smooth reset. Upgraded, Geissele triggers are also used with the SSA being used to provide a military proven and ultra reliable solution that still gives a 4.5-5.5lb trigger pull allowing for some take-up.

Our lowers feature threaded bolt catch pins, this ensures that the finish will not be damaged by use of a punch and also gives the end user an easier ability to change out the bolt catch if they prefer. When we assemble a lower in-house we use blue loctite to ensure the threaded pin does not work loose.

One of other the features built into our lowers is a tension screw which ensures a tight upper and lower fit. Each upper and lower set when destined for a rifle is hand matched to ensure the best fit and then fine tuned with the screw. This allows for a wobble free fit of both parts.

After primary assembly the gun is correctly lubed with G96+ (the only CLP to pass both US ARMY lubing and corrosion testing requirements) and test fired at our range facility.

Only then is the rifle made ready for sale. These extra lengths and quality checks ensure that you will have a reliable rifle for life when purchasing from Hunter Rifleworks.

All of our rifles come with a lifetime warranty against manufacturing defects.